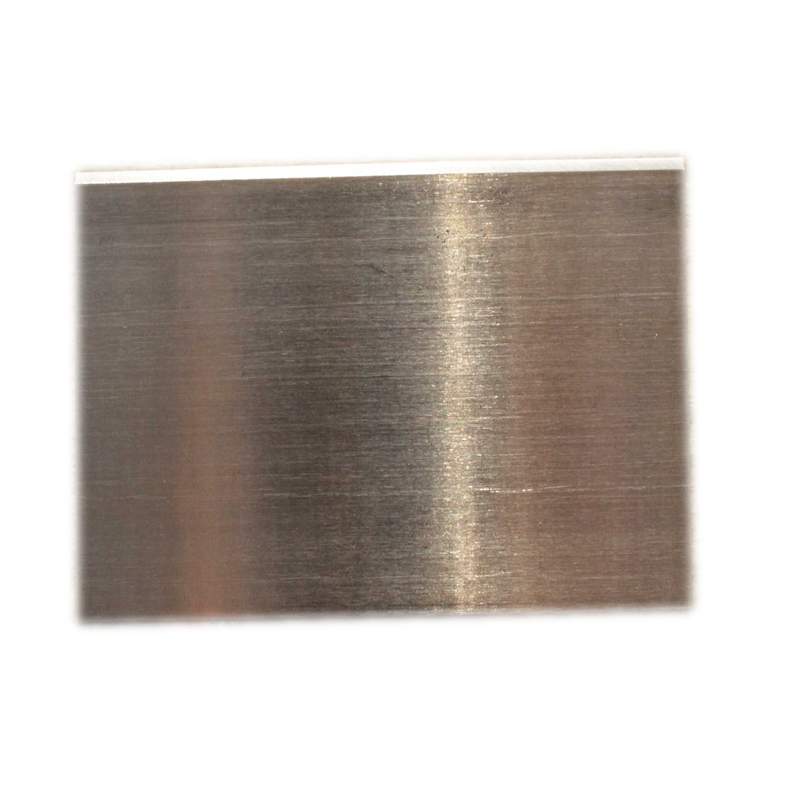

Coating doctor blade is used in coating machine, assist in an important part of a paper production, doctor blade quality directly affect the product quality and production efficiency of paper.The rapid development of paper industry began to require better adapt doctor blade to the operation of the high-speed paper machine, not only ensure the quality of paper, and can improve production efficiency.

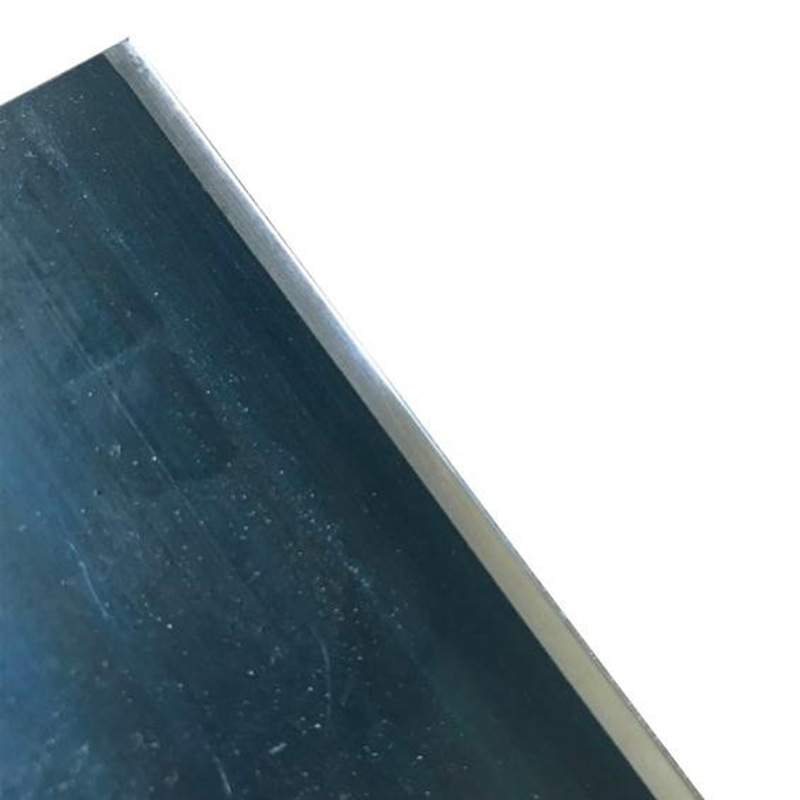

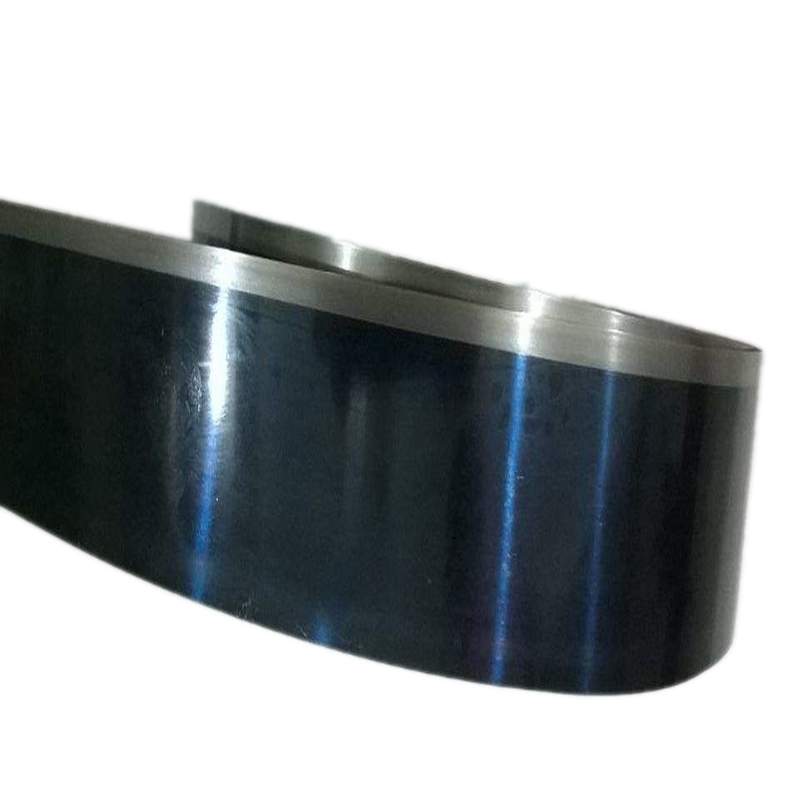

Wrinkle doctor blade and dryer surface are contact, so doctor blade material is very important, to choose appropriate to protect the cylinder surface, scrape out a good wrinkle, the hardness of the wrinkle doctor blade is slightly lower than the surface of the dryer.Too large will damage the cylinder surface, too low, the blade is easy to roll mouth, can not scraping the paper.Below are several materials suitable for scraper, can achieve satisfactory use.